Description

4HS MultiPower Overview

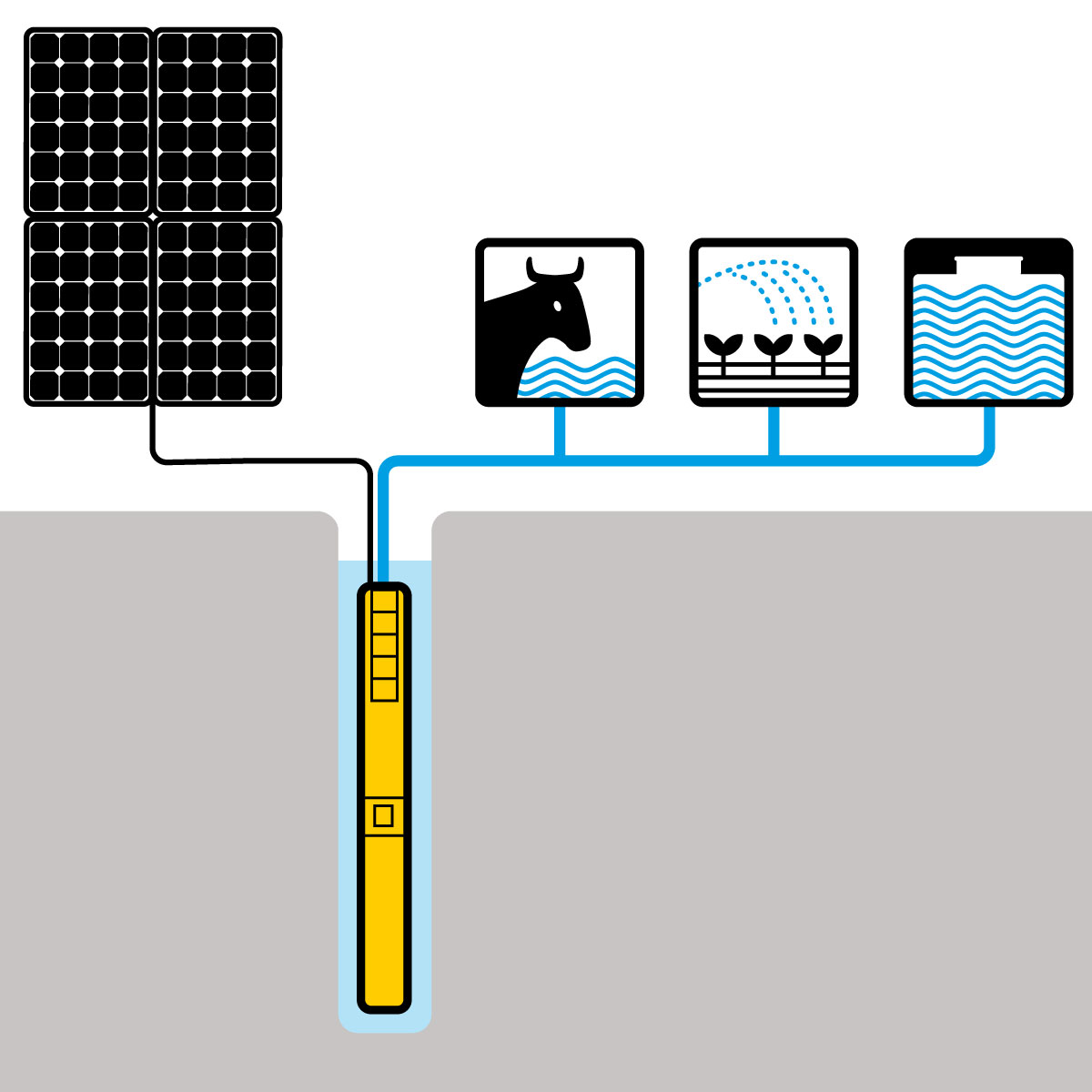

4HS MultiPower pumps powered by renewable energy sources, is a new range from 4HS pumps with built-in inverter

4HS MultiPower pumps can be powered by AC or DC with a wide range of operating voltage (90 – 265 VAC / 90 – 400 VDC). This means that 4HS MP pumps can be connected to solar panels, batteries, wind turbine and a diesel generator.

A special software algorithm allows for adjusting the hydraulic performance to each source and to the available power while maximising the amount of water pumped.

All the advantages of built-in electronics.

The built-in electronics inside the motor avoid the use of shielded cables and output filters, and it is the ideal solution for any application in remote locations without surveillance and climatically adverse.

Traditionally the solar inverter is placed above ground and, being exposed to the weather, could suffer from:

- Overheating

- Water infiltration

- Thermal shock

- Damage by animals or people

The built-in electronics are directly cooled by the water flow; the operating temperature of the electronic components is so low as to ensure considerably longer life than a surface inverter affected by high temperatures, humidity, dust and sunlight.

4HS MultiPower pump can be installed with CM MultiPower control module or without it, thus becoming a plug & pump system

If the CM MultiPower control module is not used, signal cables can be used to control pump start and stop, connecting a float switch, for example. All the protections against overload, surges and dry running are integrated into the on-board inverter.

If the signal cables are connected to the CM MultiPower control module, it is possible to:

- Control the electric parameters (current, power, voltage).

- Record and store all the alarms related to the working hours.

- Connect a pressure or a flow sensor to monitor the pump’s performance.

- Connect a pressure or float switch.

- Provide an alarm digital output for remote control.

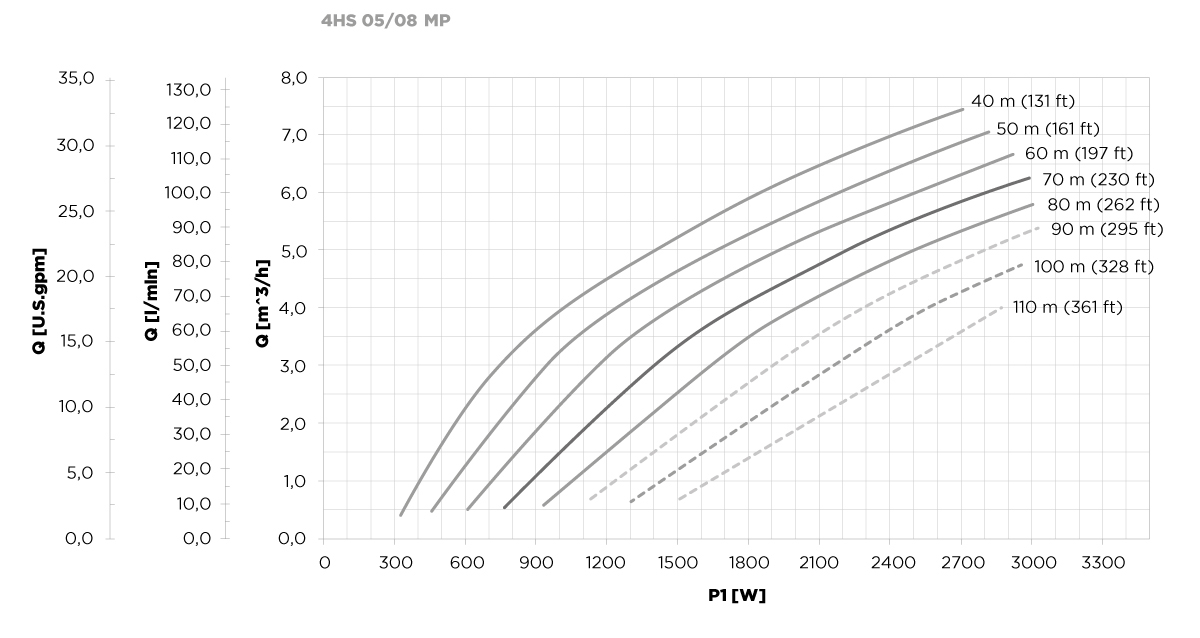

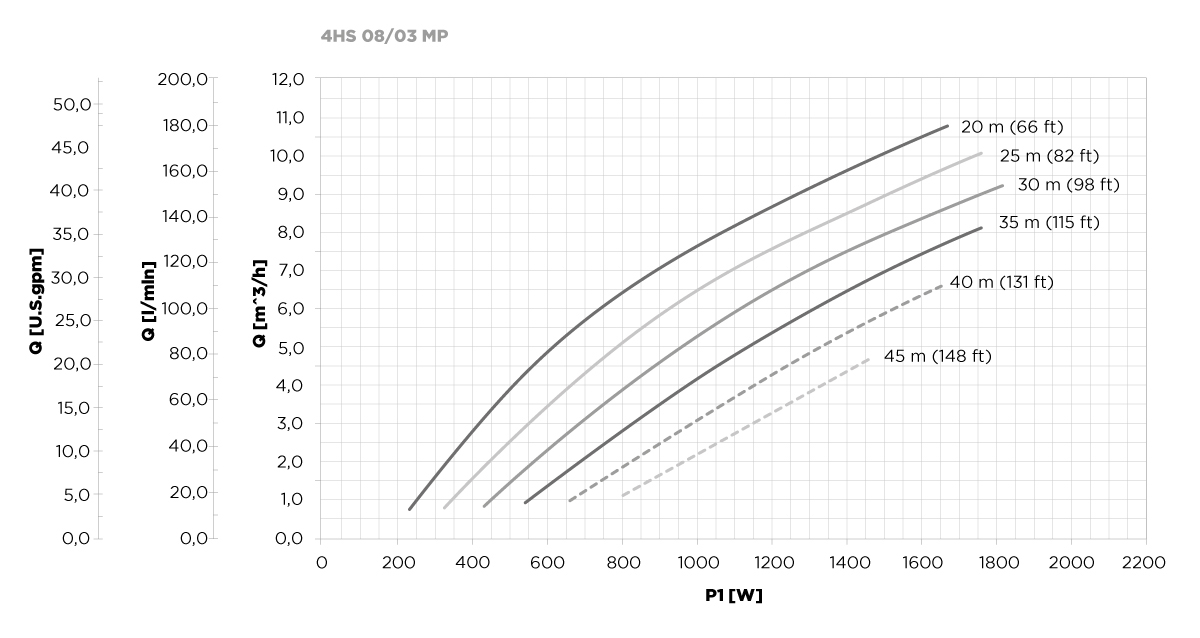

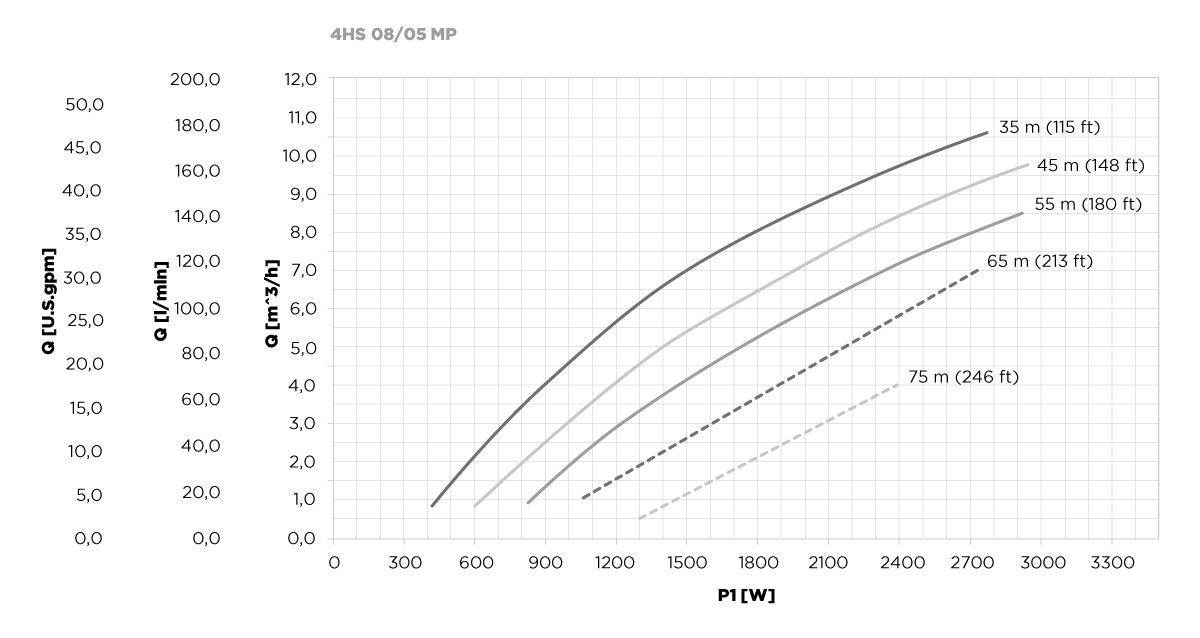

MPPT: always the maximum power available.

Based on the varying conditions of solar irradiation and temperature, MPPT (Maximum Power Point Tracking) maximises the electrical power drawn from the panels and therefore the amount of water pumped.

The greater the solar irradiation the faster the pump’s rotation speed, and consequently water flow increases.

When solar irradiation decreases (due to clouds or the different times of day), the pump reduces frequency and therefore the flow, but it continues to provide water until the irradation falls below a minimum level necessary to ensure operation.

4HS Multipower Technical Specifications

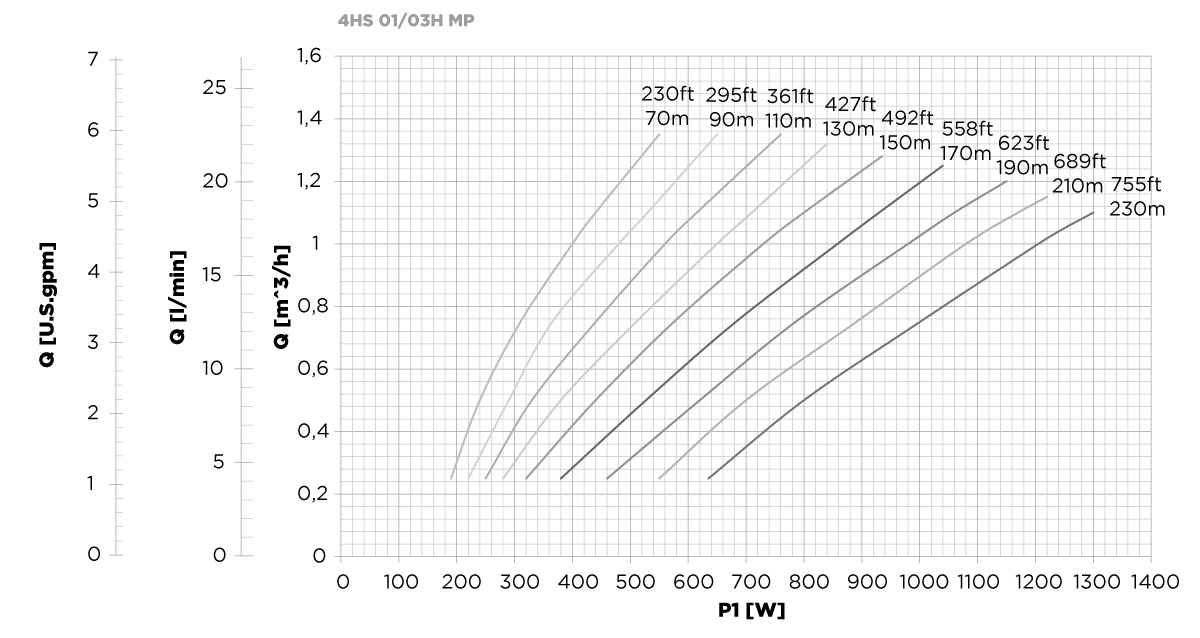

| 4HS 01/03H MP | |

| Voltage | 90-400 VDC 90-265 VAC |

| Max current | 13 A (100 VDC) 13 A (100 VAC) |

| Power factor | 1 |

| Max power P1 | 1300 W |

| Length | 1385 mm |

| Discharge | 1 1/4” |

| Pump weight | 21 kg |

| Max diameter* | 99 mm |

| Packing dimensions | 120 x 20 x 29 cm |

| Total weight | 22 Kg |

* Max. external diameter including cable and cable cover

General specifications

| 4HS MultiPower | |

| Max liquid temperature | 35 °C (92 °F) |

| Min liquid cooling speed | 0.2 m/s |

| Characteristics of the pumped liquid | clean, chemically not aggressive, not explosive, without solid and fibre content, with max. 50 g/m3 sand content |

| Protection grade | IP68 |

| Maximum immersion depth | 150 m |

| Materials | Motor and pump in AISI 304 stainless steel |

| Cable | Flat cable ACS – WRAS – KTM approved |

| CM MultiPower Control Module | |

| Max ambient temperature | 50 °C (122 °F) |

| Protection grade | IP55 |

| Materials | Aluminium enclosure, PVC labels , cable gland in polyamide (PA), display membrane in polyester (PE) |

| Analog input | 2 input 4-20 mA + 2 input 4-20 mA or 0-10 V settable by the user |

| Digital input | 4 input N.A or N.C settable by the user |

| Digital output | 2 relays output 5 A , 250 VAC, N.O. or N.C settable by the user |

| User display | display LCD backlit, 16 characters x 2 rows, 5 buttons |

| Short-circuit protection | fuse |

| Certifications | |

| CE |

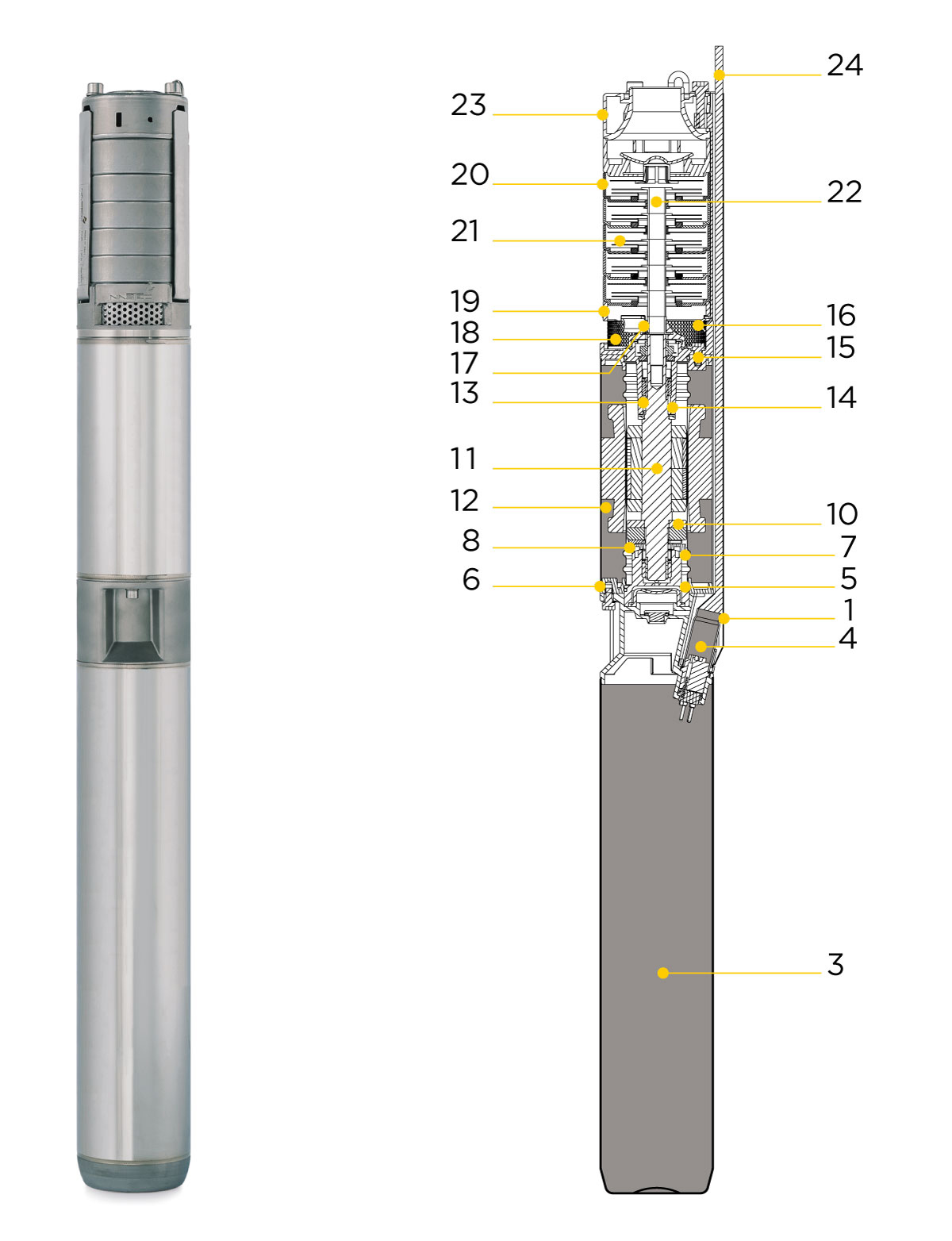

Materials

| RIF | Description | Material |

| 1 | Power supply cable with removable connector for drinking water applications | AISI 304 + ACS-KTM-WRAS compliant |

| 3 | MINT: Electronic Integrated Module | |

| 4 | Cable guard | AISI 304 |

| 5 | Lower thrust bearing | AISI 304 |

| 6 | Rubber diaphragm | EPDM |

| 7 | Lower bush | SiC |

| 8 | Tilting disc | AISI 304 |

| 9 | Pads | AISI420j |

| 10 | Carbon disc | CTI25 |

| 11 | Shaft with rotor | AISI 431 |

| 12 | Canned type stator | AISI 304 |

| 13 | Upper bush | SiC |

| 14 | Upper thrust bearing | Teflon |

| 15 | Ceramized sleeve | AISI 304 + Ceramica |

| 16 | Mechanical seal | SiC |

| 17 | Rotating sandguard | NBR |

| 18 | Pump filter | AISI 304 |

| 19 | Pump bracket | AISI 304 |

| Centrifugal pump | ||

| 20 | Diffusers | AISI 304 |

| 21 | Impellers | AISI 304 |

| 22 | Pump shaft | AISI 304 |

| 23 | Discharge | AISI 304 |

| 24 | Straps | AISI 304 |

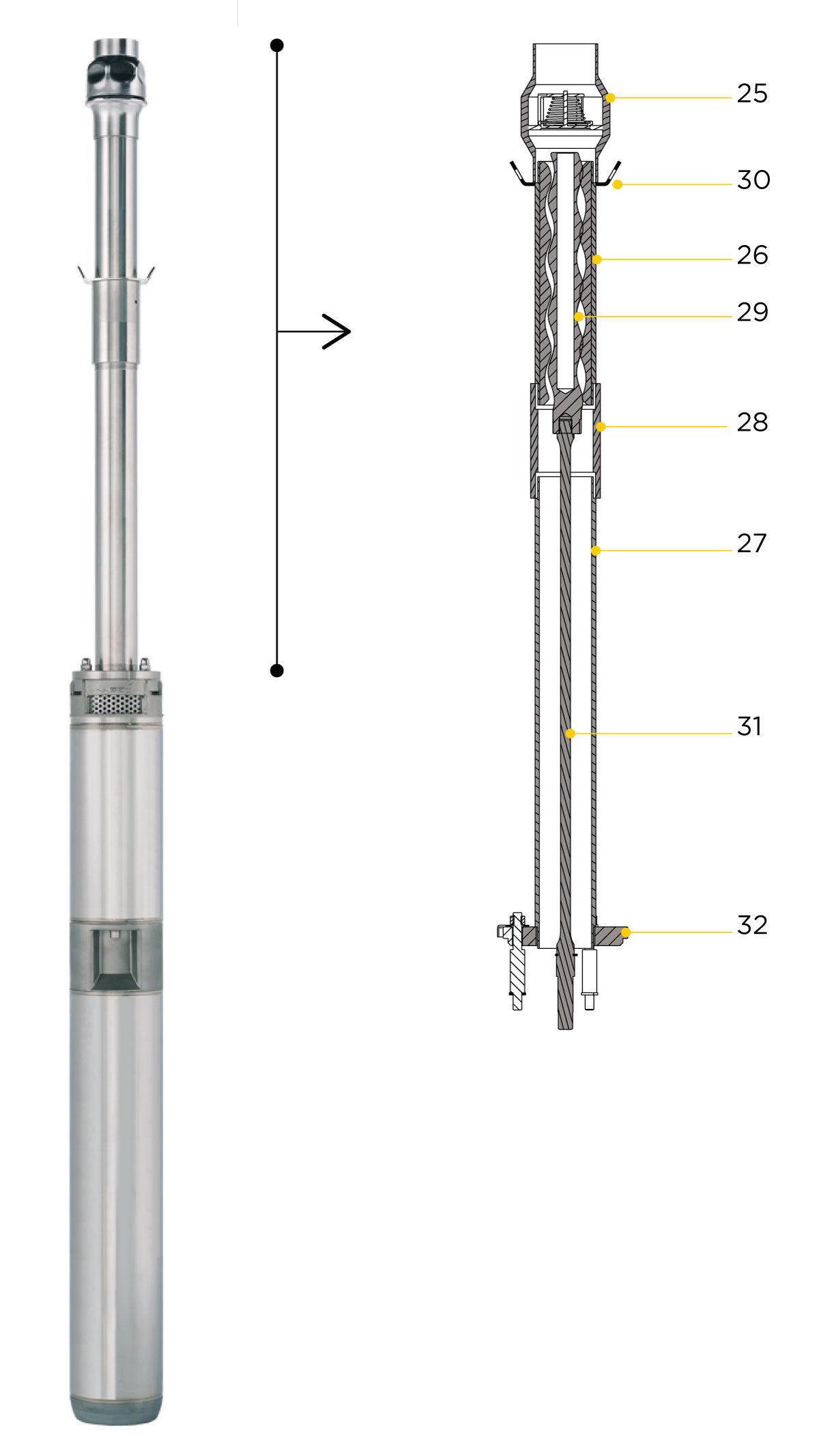

| Helicoidal rotor pump | ||

| 25 | No-return valve | AISI 304 |

| 26 | Helicoidal stator | EPDM + AISI 304 |

| 27 | Supporting pipe | AISI 304 |

| 28 | Junction | AISI 304 |

| 29 | Helicoidal rotor | AISI 304 cromato |

| 30 | Safety hook | AISI 304 |

| 31 | Flexible shaft | AISI 316 |

| 32 | Pump adaptor | AISI 304 |