Description

Overview

Variable speed controller for pumps

VASCO – VAriable Speed COntroller is a purpose-built family of variable frequency drives, designed to control and protect pumping systems based on changing pump speed.

From water supply for domestic, irrigation, commercial and industrial applications, to heating and air conditioning, from filtering to pressure washing, the range perfectly fits any new or existing application ensuring:

- energy and cost saving

- simplified installation

- longevity of pumping system

- greater reliability

Maximum flexibility in several areas of application

Device units are extremely compact and, connected to any pump on the market, will manage the operation of the pump to maintain a constant desired physical dimension (such as pressure, flow, temperature or other). The pumping system runs only at the speed necessary to meet the user’s requirements, ensuring energy savings and extending the life of the system. It also provides motor protection and monitoring, such as:

- protection against overload and dry running

- indication of input current and supply voltage

- integrated soft start and soft stop functions, extending the life of the system and reducing peak absorption

- recording running hours and loggings errors and alarms reported by the system

- It can control a second or third pump at constant speed DOL (DOL: Direct On Line)

- connect to other devices to get combined operation

The compact body is constructed entirely of aluminium, making device extremely solid, lightweight and easily cooled, adding to the unit’s versatility.

The IP55 degree of protection makes it possible to install it virtually anywhere, including humid and dusty environments. The illuminated liquid crystal display ensures it is easy to operate, and a buzzer provides an immediate indication of alarm.

Installing VASCO – VAriable Speed COntroller is simple and intuitive, requiring just a few quick steps

- Connect device to the power supply.

- Connect device to the pump.

- Connect device to the sensor, located wherever in the piping you want to maintain the desired constant physical dimension (pressure, flow, liquid temperature, etc.)

- Set device to configure the pump to the system and the desired performance.

When first powering the device, a quick initial wizard is required for complete configuration of the drive. Additional parameters can be configured later by entering three different setting levels:

- End user level. The only level which can be accessed without a password. It allows the user to monitor electrical and hydraulic parameters and the status of device and pump.

- Installer level. In this level the installer can configure pump system to the characteristics of the hydraulic system. A password is required.

- Advanced level. This level allows the electrical configuration of device according to the pump. Another password is required.

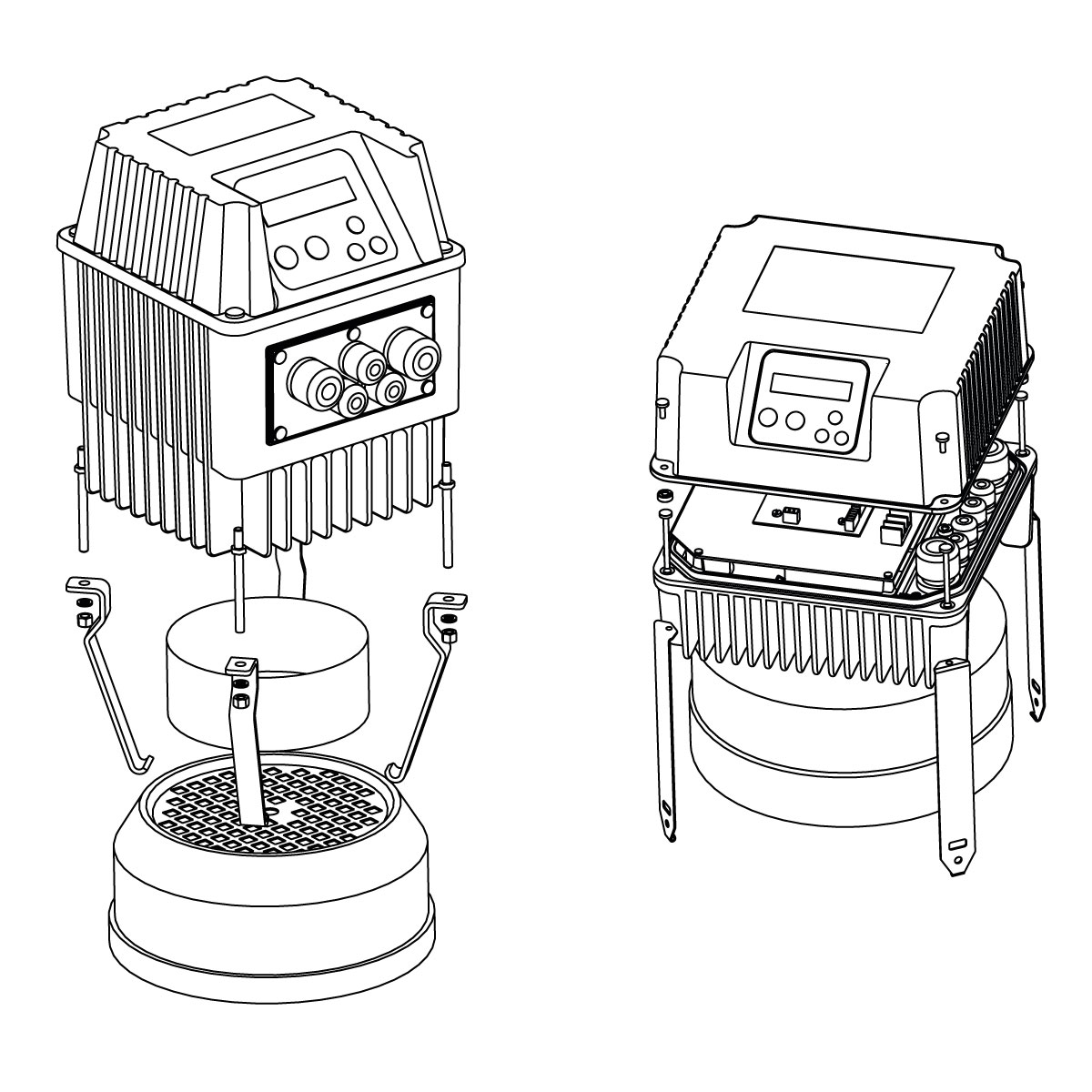

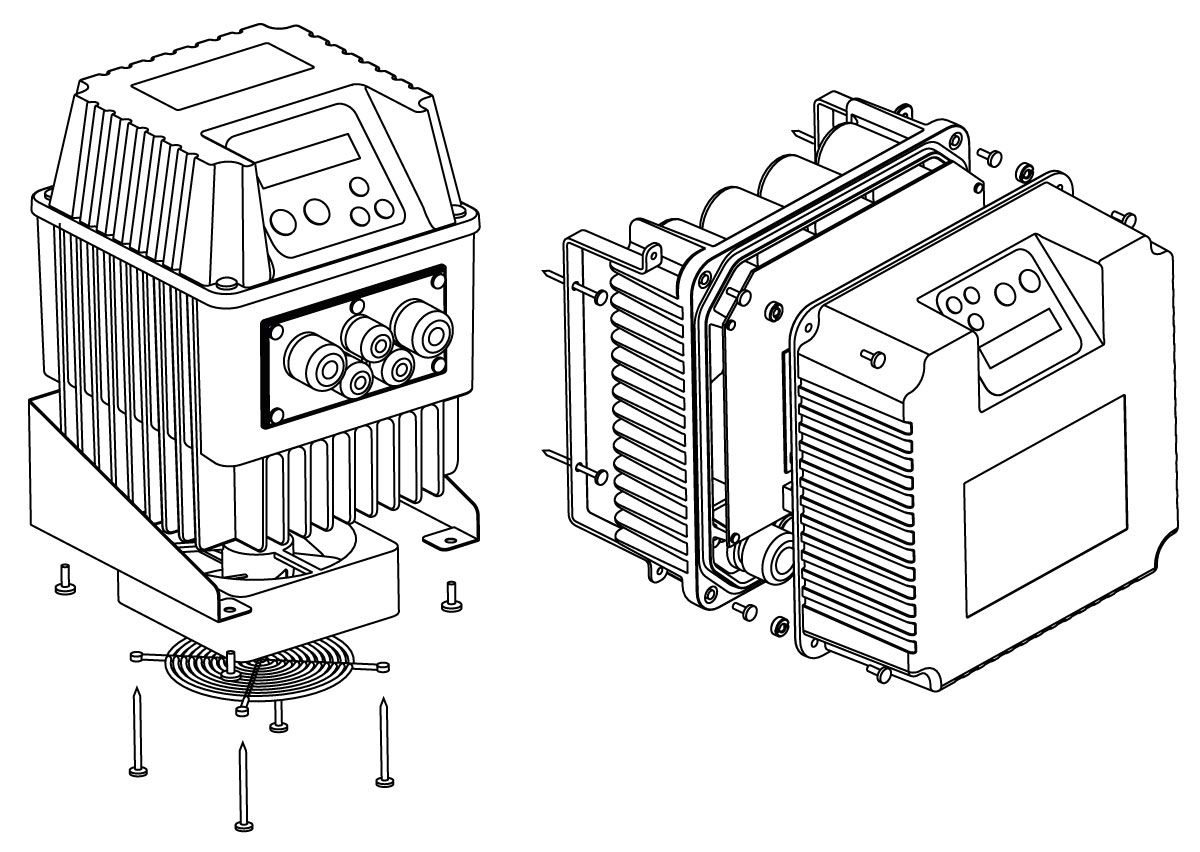

The device can be installed directly on the motor with a supplied installation kit.

Motor kit

It is cooled by the motor cooling fan. Motor kit consists of 4 special clamps (or flange adapter) to secure the device to the motor fan cover (or motor feet).

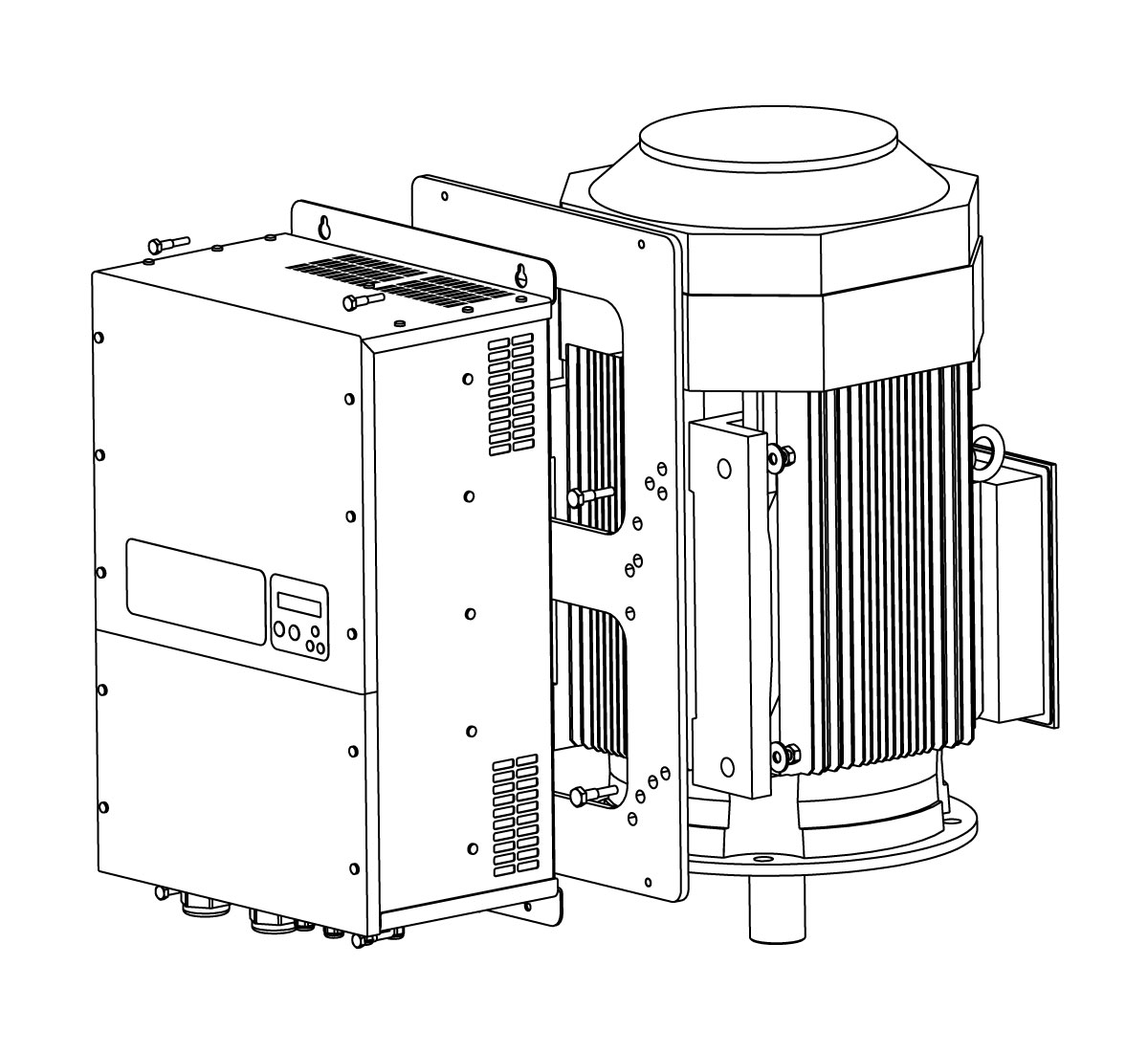

The device can be installed directly to the wall with a supplied installation kit.

Wall kit

It is cooled by an external cooling fan attached to the inverter radiator. A special metal bracket is supplied for device to be mounted on the wall.

Software is the result of many years experience

Software implemented in each drive of VASCO – VAriable Speed COntroller range is the result of a long-time experience in solving customer requests and constantly following new drive applications.

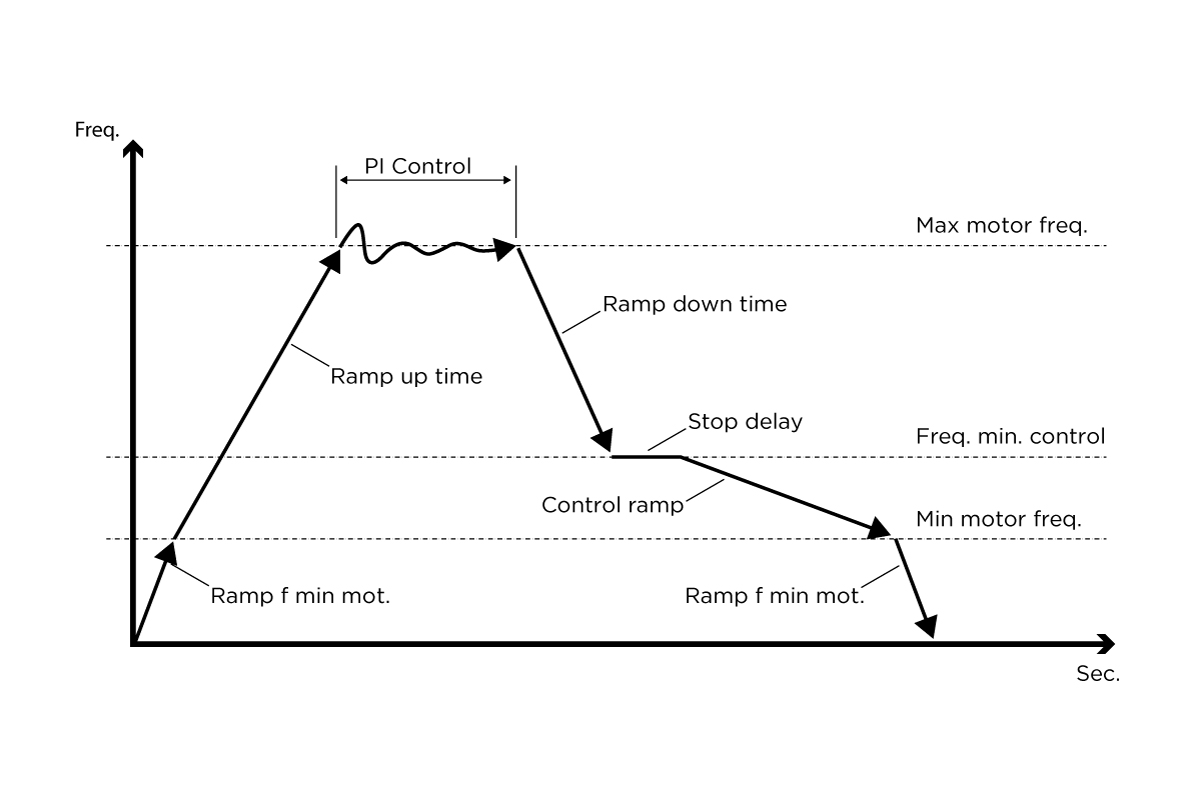

Minimum motor frequency.

This parameter prevents motor operation below a certain frequency, thus avoiding damage to the thrust bearing of the submersible motors.

Minimum motor frequency ramp.

Motor can accelerate from 0 to the minimum motor frequency following a very fast ramp and then go through a slower ramp.

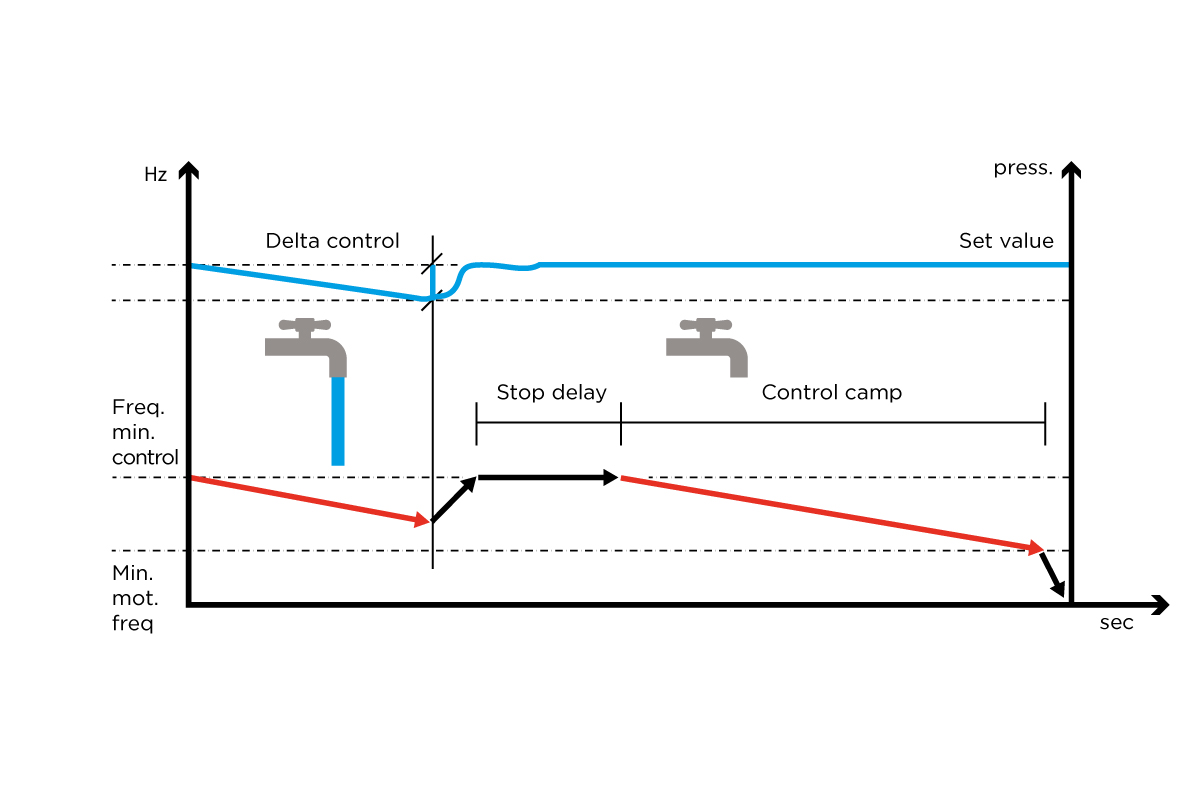

Intelligent stop of pump at no flow condition.

Below minimum control frequency, the device gradually reduces the pump speed while monitoring the pressure transducer signal. If this value is maintained close to the set pressure, the device will reduce furthermore the output frequency till stopping definitely the pump.

Maximum and minimum alarm pressure.

When the pressure rises above a certain settable pressure value, the device will stop the pump to prevent damage to the hydraulic components in the system. Similarly, if the pressure drops below a certain pressure an alarm is triggered and the pump is stopped.

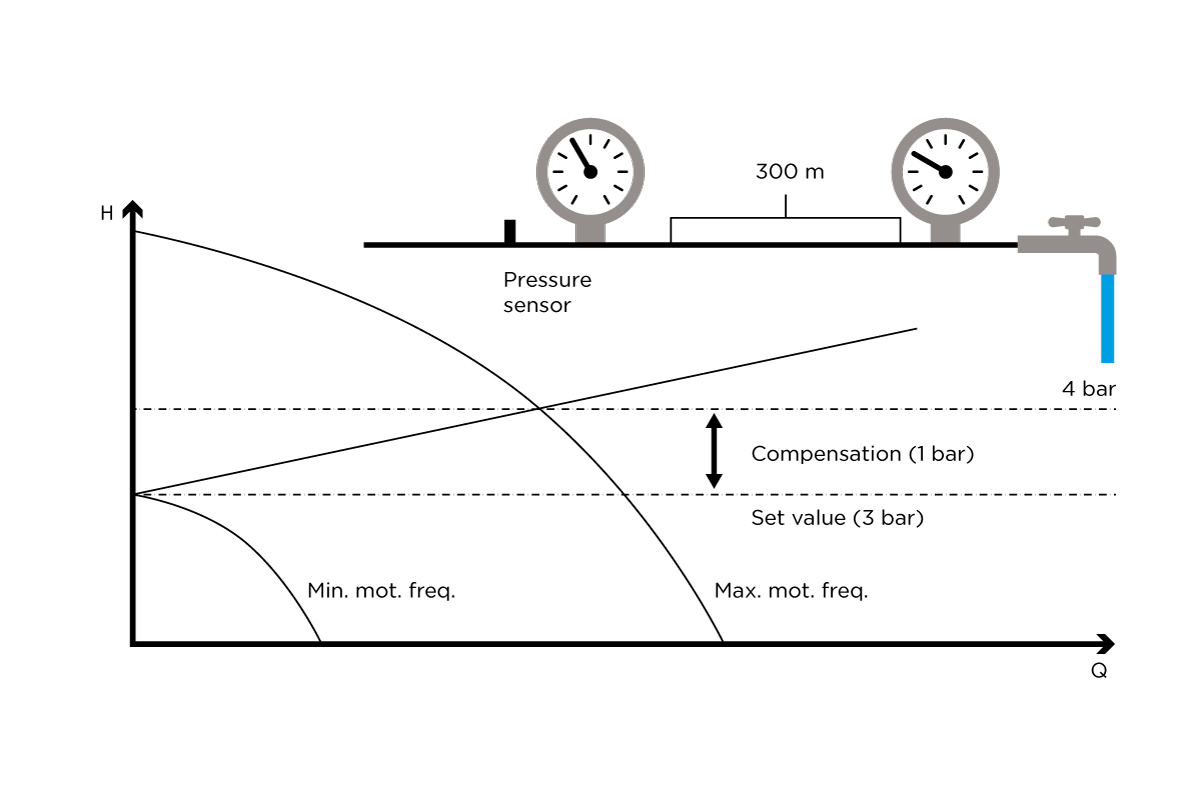

Loss compensation proportional to the water flow.

If the pressure sensor is placed near the pump, with the increase in flow the pressure value at the furthest outlet is lower than the set pressure. It is possible to vary the set pressure in proportion to the frequency to compensate pressure loss in the pipes.

Dry running alarm via cosphi value.

If the pump runs dry, its cosphi value drops below a settable cosphi value, and the device stops the pump after 3 seconds. Device will try to make 5 attempts every 10, 20, 40, 80 and 160 minutes, after which it will trigger an alarm and stop the pump if the condition persists.

V/f programmable curve.

VASCO – VAriable Speed COntroller offers two different methods of torque control (voltage) versus pump speed (frequency):

- constant torque (linear V/f)

- quadratic variable torque (squared V/f)

For centrifugal pumps, energy savings can be obtained by selecting squared V/f control.

Settable carrier frequency between 2.5, 4, 6, 8, 10 kHz

If the device controls a submersible pump with long cables, it is possible to decrease the carrier frequency value to ensure longer motor life.

Technical Specifications

| Model | Vin ± 15% | Max V out | Max I out | P2 motor power* | Size |

| VAC | VAC | A | kW | ||

| V 209 | 1 x 230 | 1 x Vin | 9 | 1,1 | 1 |

| 1 x 230 | 3 x Vin | 7 | 1,5 | 1 | |

| V 214 | 1 x 230 | 1 x Vin | 9 | 1,1 | 1 |

| 1 x 230 | 3 x Vin | 11 | 3 | 1 | |

| V 218 | 1 x 230 | 3 x Vin | 18 | 4 | 2 |

| V 225 | 1 x 230 | 3 x Vin | 25 | 5,5 | 2 |

| V 230 | 1 x 230 | 3 x Vin | 30 | 7,5 | 3 |

| V 238 | 1 x 230 | 3 x Vin | 38 | 9,3 | 3 |

| V 306 | 3 x 230 | 3 x Vin | 6 | 1,1 | 1 |

| V 309 | 3 x 230 | 3 x Vin | 9 | 2,2 | 1 |

| V 314 | 3 x 230 | 3 x Vin | 14 | 3 | 2 |

| V 318 | 3 x 230 | 3 x Vin | 18 | 4 | 2 |

| V 325 | 3 x 230 | 3 x Vin | 25 | 5,5 | 2 |

| V 330 | 3 x 230 | 3 x Vin | 30 | 7,5 | 2 |

| V 338 | 3 x 230 | 3 x Vin | 38 | 9,3 | 3 |

| V 348 | 3 x 230 | 3 x Vin | 48 | 11 | 3 |

| V 365 | 3 x 230 | 3 x Vin | 65 | 15 | 3 |

| V 375 | 3 x 230 | 3 x Vin | 75 | 18,5 | 3 |

| V 385 | 3 x 230 | 3 x Vin | 85 | 22 | 3 |

| V 3118 | 3 x 230 | 3 x Vin | 118 | 30 | 4** |

| V 3158 | 3 x 230 | 3 x Vin | 158 | 37 | 4** |

| V 3185 | 3 x 230 | 3 x Vin | 185 | 45 | 4** |

| V 3215 | 3 x 230 | 3 x Vin | 215 | 55 | 4** |

| V 3268 | 3 x 230 | 3 x Vin | 268 | 75 | 4** |

| V 406 | 3 x 380-460 | 3 x Vin | 6 | 2,2 | 1 |

| V 409 | 3 x 380-460 | 3 x Vin | 9 | 4 | 1 |

| V 414 | 3 x 380-460 | 3 x Vin | 14 | 5,5 | 2 |

| V 418 | 3 x 380-460 | 3 x Vin | 18 | 7,5 | 2 |

| V 425 | 3 x 380-460 | 3 x Vin | 25 | 11 | 2 |

| V 430 | 3 x 380-460 | 3 x Vin | 30 | 15 | 2 |

| V 438 | 3 x 380-460 | 3 x Vin | 38 | 18,5 | 3 |

| V 448 | 3 x 380-460 | 3 x Vin | 48 | 22 | 3 |

| V 465 | 3 x 380-460 | 3 x Vin | 65 | 30 | 3 |

| V 475 | 3 x 380-460 | 3 x Vin | 75 | 37 | 3 |

| V 485 | 3 x 380-460 | 3 x Vin | 85 | 45 | 3 |

| V 4118 | 3 x 380-460 | 3 x Vin | 118 | 55 | 4** |

| V 4158 | 3 x 380-460 | 3 x Vin | 158 | 75 | 4** |

| V 4185 | 3 x 380-460 | 3 x Vin | 185 | 90 | 4** |

| V 4215 | 3 x 380-460 | 3 x Vin | 215 | 110 | 4** |

| V 4268 | 3 x 380-460 | 3 x Vin | 268 | 132 | 4** |

* Typical motor power. It is recomended to refer to the rated motor current when selecting the model.

** Size 4 available from February 2019.

General specifications

| Rated frequency | 50 – 60 Hz (+/- 2%) |

| Ambient temperature | -10° -50°C (14° – 122°F) |

| Max. altitude at rated current | 1000 m |

| Protection degree | IP55 (NEMA 4) Sizes 1, 2 IP54 (NEMA 12) Sizes 3, 4 |

| Settable digital outputs, N.O. or N.C. | 1. Motor run signal 2. Alarm signal 3. DOL 1 pump signal 4. DOL 2 pump signal |

| Analog inputs (10 or 15 VDC) | 1. 4-20 mA 2. 4-20 mA 3. 4-20 mA / 0 – 10 VDC 4. 4-20 mA / 0 – 10 VDC |

| Digital inputs | 4 digital inputs, configurable N.O. or N.C. for motor run/stop |

| RS485 MODBUS RTU, Bluetooth® SMART (4.0) |