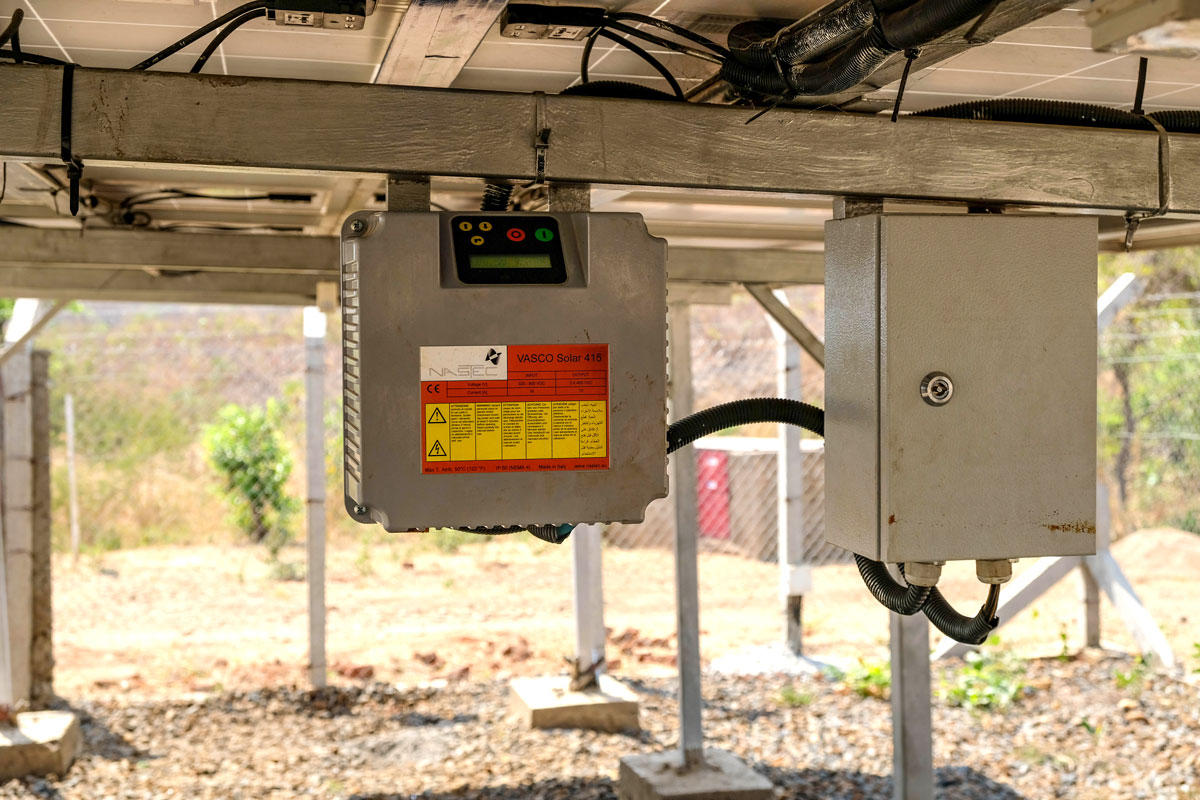

VASCO Overview

VASCO: The inverter for solar pumping applications.

It is able to convert DC voltage coming from solar panels into AC voltage for powering any pump driven by a three-phase motor.

Pump speed is constantly adapted to available solar irradiation thus maximising the amount of pumped water and making possible operation even in conditions of low sunlight.

It also offers complete pump protection against surges, overloads and dry running.

VASCO – VAriable Speed COntroller – Solar MP

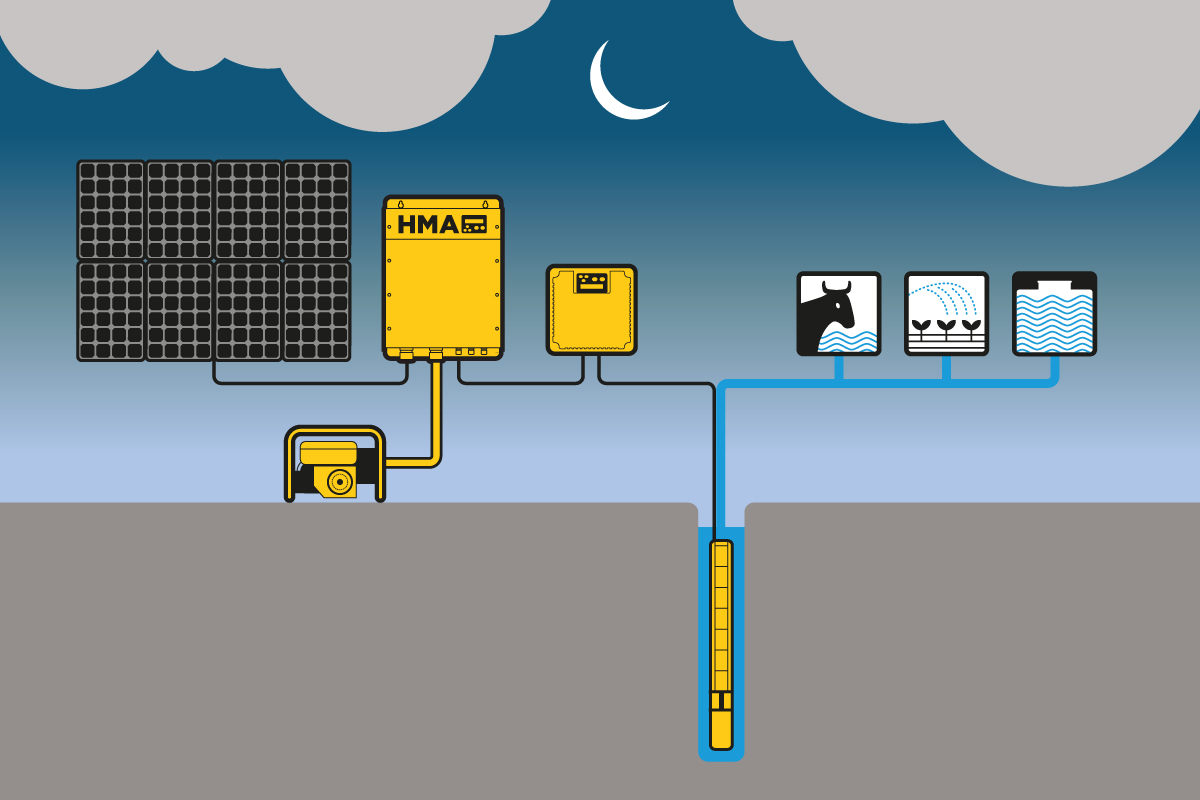

The inverter in MP (MultiPower) version can be powered in DC by solar panels or in AC by network or generator to ensure the functioning of the pump at any hour of the day.

This controls the peaks of water demand using AC input to avoid the oversizing of the photovoltaic system.

HMA accessory, used in combination with Solar MP models, manages independently the exchange from a source of energy to another on the basis of several options that can be select by the user:

- irradiance level.

- hour of the day.

- achievement of the requested daily range.

- remote control through digital command.

VASCO: Designed to resist

The device is built entirely of aluminium to ensure maximum cooling and durability. All other metal parts are made using AISI 304 stainless steel and therefore resistant to corrosion.

Two independent external fans and an internal fan provide perfect cooling. Their operation is adjusted according to actual thermal conditions, thus extending life.

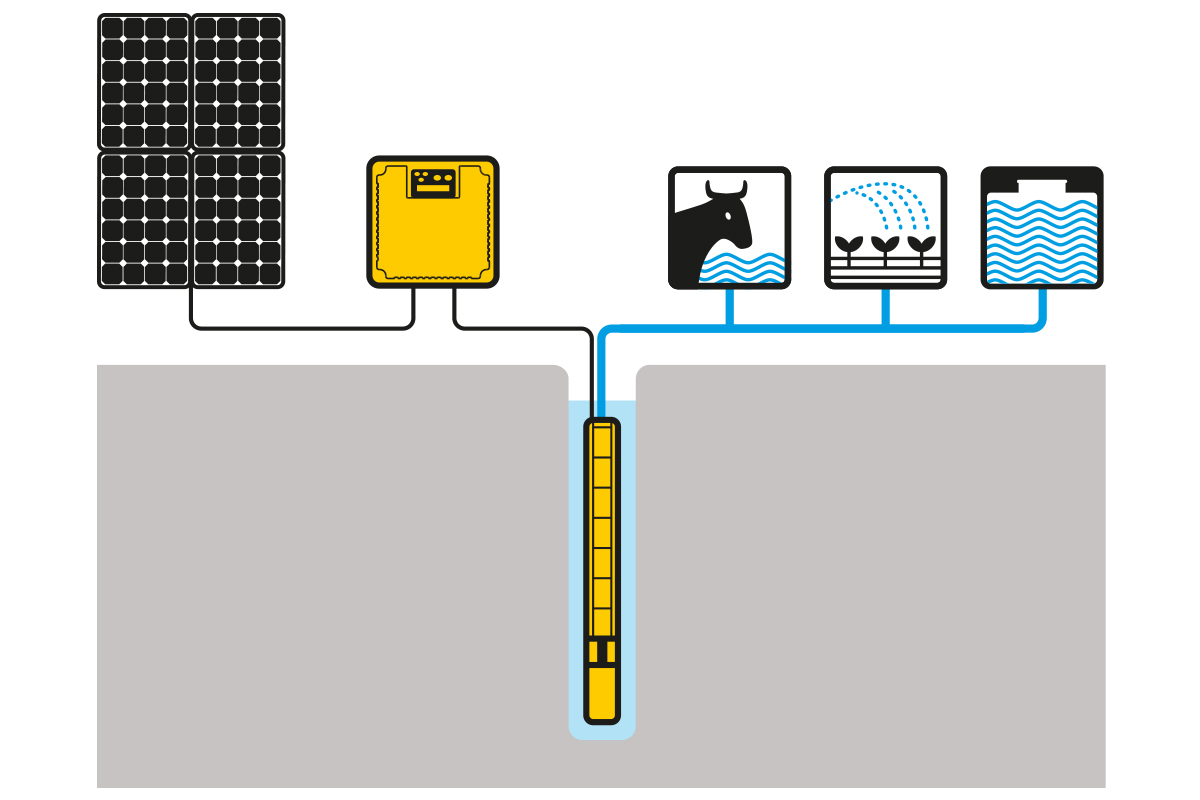

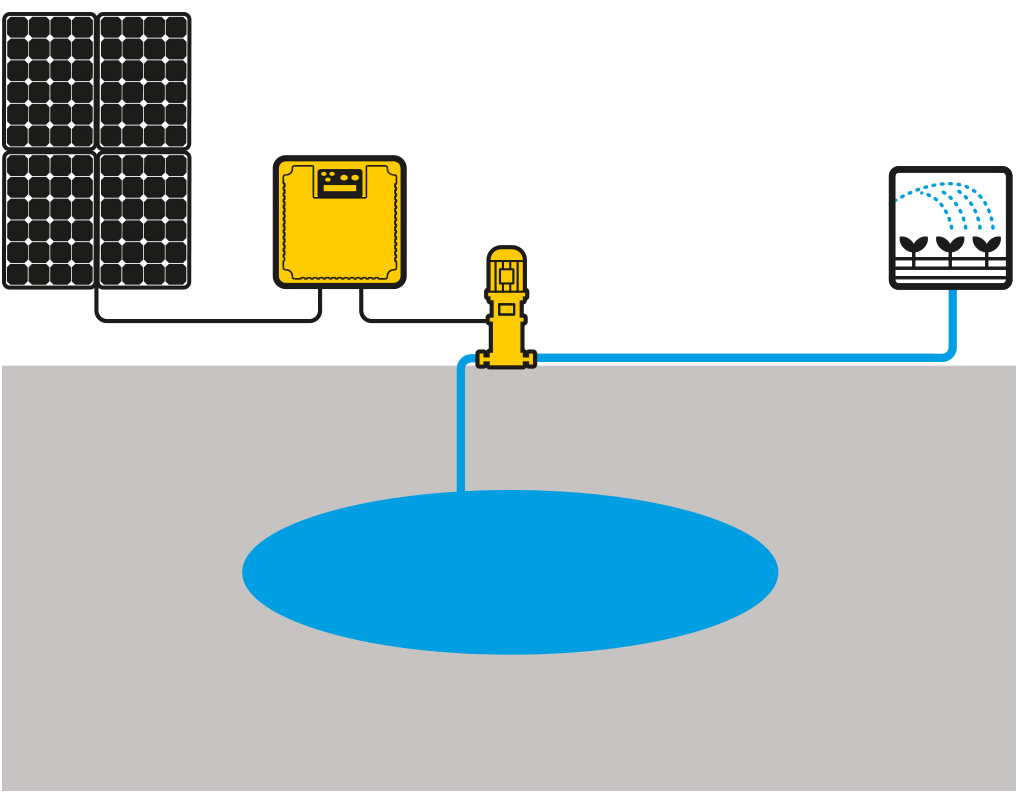

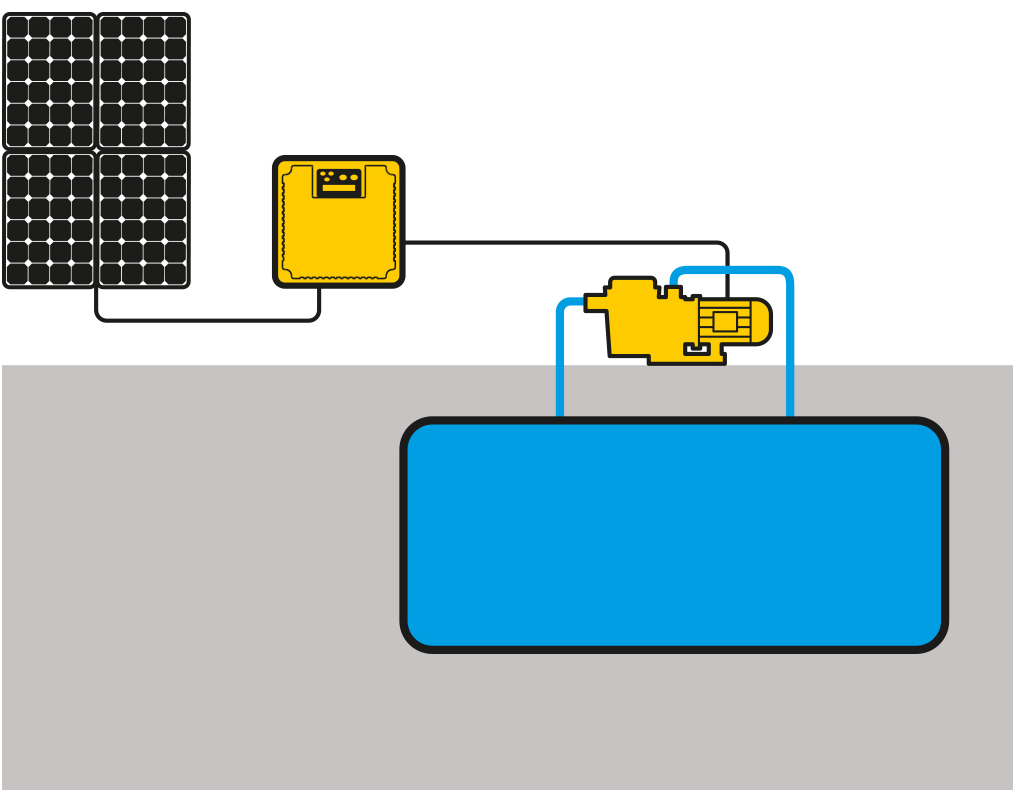

Maximum flexibility

When using surface pumps, device can be used for an irrigation system drawing water from a nearby water supply, or powering a pool pump at no cost.

When using submersible pumps, it is possible to fill tanks for watering livestock or simply irrigate lawns or crops.

MPPT: always the maximum power available

Based on the varying conditions of solar irradiation and temperature, MPPT (Maximum Power Point Tracking) maximises the electrical power drawn from the panels and therefore the amount of water pumped.

The greater the solar irradiation the faster the pump’s rotation speed, and consequently water flow increases.

When solar irradiation decreases (due to clouds or the different times of day), the pump reduces frequency and therefore the flow, but it continues to provide water until the irradation falls below a minimum level necessary to ensure operation.

Monitoring parameters

VASCO Solar – VAriable Speed COntroller is equipped with a backlit alphanumeric display and is designed to monitor key electrical parameters like input voltage, power, current and motor power factor.

It is also possible to connect a pressure or flow sensor to monitor performance levels.

In the diagnosis menu are recorded inverter and motor hours, operation statistics, and the last eight alarms occurred. The programming menus are password-protected to prevent unwanted tampering.

Advanced connectivity

The device can be connected to:

- An alarm

- A motor run/stop signal

- A pressure sensor or a flow sensor for monitoring

- Up to 4 digital inputs for pump start and stop (float switch, level sensors, etc.)

- Modbus RTU

Complete pump protection

The device is able to protect the pump against overload and dry running.

Dry running protection is performed by monitoring the motor’s power factor and therefore probes are not required.

The device also protects itself against surges and overheating.

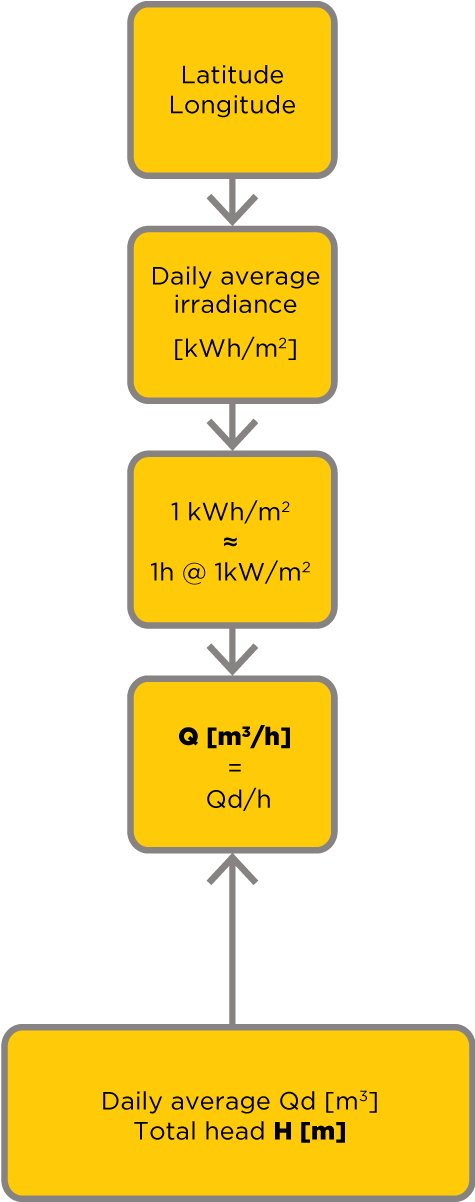

PV system sizing

The pumping system must be designed taking into account the required daily flow rate, total head and the installation site.

In particular, the choice of the pump must be made considering the average daily solar irradiation.

Once the appropriate pump has been identified, it is necessary to know:

- Rated pump power (P2)

- Electrical motor power (P1). P1 can be derived by dividing P2 by motor efficiency.

- Rated motor current

- Rated motor voltage

3 x 230 VAC or

3 x 400 VAC

The model to be used is determined by considering voltage and rated motor current.

To ensure maximum performance, the solar system – consisting of one or more strings of solar panels connected in series – must provide:

Electrical motor power (P1). ùThe photovoltaic power (Wp) must be at least equal to the electric motor power (P1). Typically, taking into account the efficiency loss due to panel temperature, it is recommended to increase Wp by 15% with respect to P1.

Rated motor voltage. The rated voltage of each string of solar panels (Vmp) must be at least equal to the rated motor voltage multiplied by the factor 1.4.

The open-circuit voltage of each string (Voc) must be less than device maximum operating voltage.

Example

Pump nameplate

Rated motor power: P2 = 3 kW

Electric motor power: P1 = 4 kW

Rated motor current: 8.3 A

Rated motor voltage: 3 x 400 VAC

VASCO Solar selection

The rated motor voltage being 400 VAC and the rated current 8.3 A, the most suitable model for the application is VS 409.

PV system sizing

PV panels used:

Wp = 240 W

Vmp = 30 VDC

Voc = 37 VDC

Imp = 8 A

Since P1 = 4 kW the required electrical power is increased by 15% so Wp = 4.6 kW.

To develop 4.6 kW 19 panels of 240 W are needed.

Vmp = 19 x 30 = 570 VDC is greater than the rated motor voltage multiplied by 1.4 (400 x 1.4 = 560 VDC) and

Voc = 19 x 37 = 703 VDC is less than the maximum voltage of VASCO Solar 409 (850 VDC).

For this reason a single string of 19 panels can be installed.

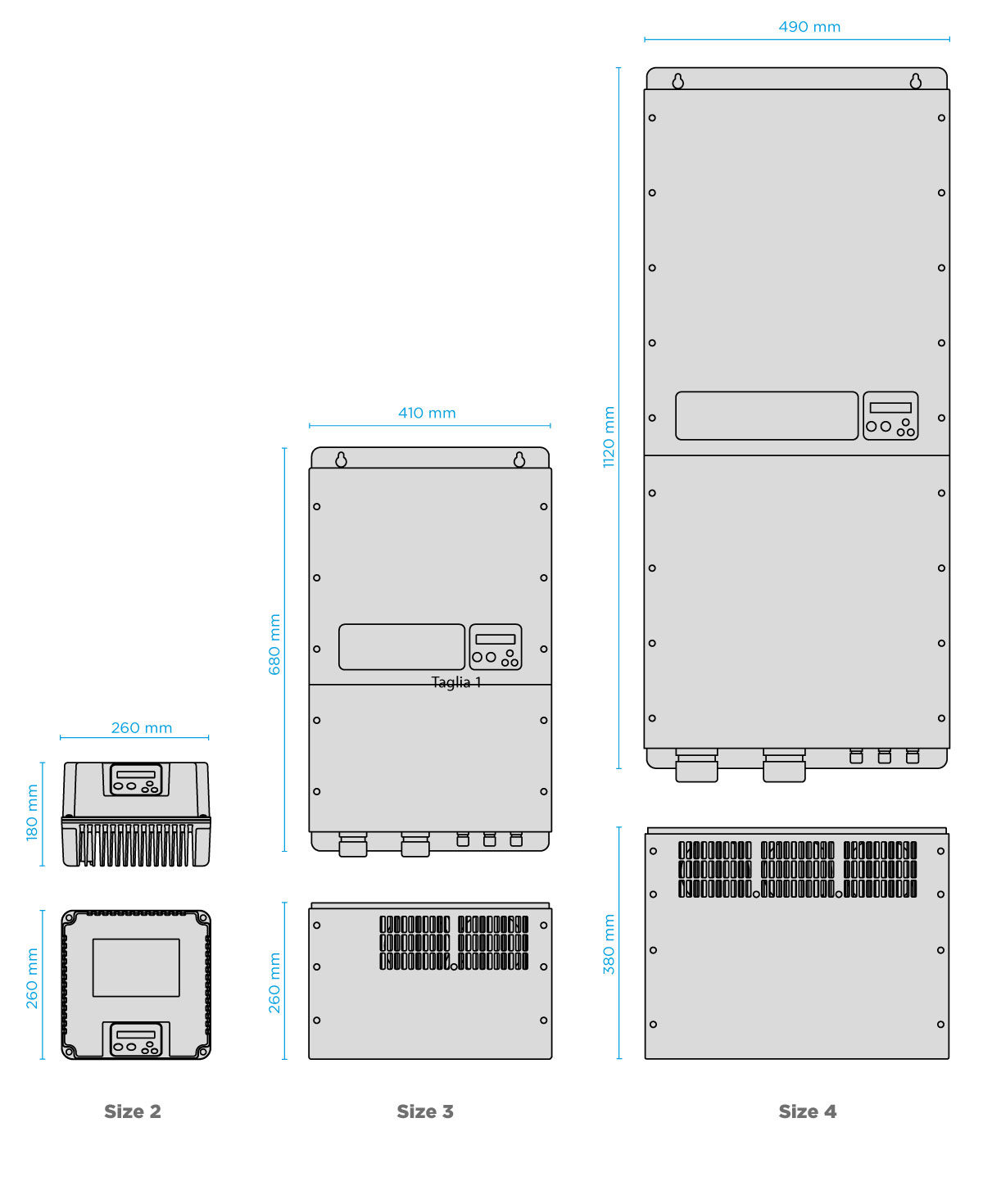

VASCO Technical Specifications

| Model | Vin DC | Vin AC* | Vin, P1 nom** | Max Vout | Max I out | Typical motor P2*** | Weight | Size | |

| VDC | VAC | VDC | VAC | A | VAC | kW | Kg | ||

| VS 212 | 160 – 650 | 3×190-520 | > 320 | 3 x 230 | 12 | 3 x 230 | 2,2 | 8,2 | 2 |

| VS 409 | 320 – 850 | 3×190-520 | > 560 | 3 x 400 | 9 | 3 x 400 | 3 | 8,3 | 2 |

| VS 412 | 320 – 850 | 3×190-520 | > 560 | 3 x 400 | 12 | 3 x 400 | 4 | 8,5 | 2 |

| VS 415 | 320 – 850 | 3×190-520 | > 560 | 3 x 400 | 15 | 3 x 400 | 5,5 | 8,5 | 2 |

| VS 418 | 320 – 850 | 3×190-520 | > 560 | 3 x 400 | 18 | 3 x 400 | 7,5 | 8,5 | 2 |

| VS 425 | 320 – 850 | 3×190-520 | > 560 | 3 x 400 | 25 | 3 x 400 | 11 | 8,5 | 2 |

| VS 430 | 320 – 850 | 3×190-520 | > 560 | 3 x 400 | 30 | 3 x 400 | 15 | 8,7 | 2 |

| VS 438 | 320 – 850 | 3×190-520 | > 560 | 3 x 400 | 38 | 3 x 400 | 18,5 | 28 | 3 |

| VS 448 | 320 – 850 | 3×190-520 | > 560 | 3 x 400 | 48 | 3 x 400 | 22 | 28 | 3 |

| VS 465 | 320 – 850 | 3×190-520 | > 560 | 3 x 400 | 65 | 3 x 400 | 30 | 28 | 3 |

| VS 485 | 320 – 850 | 3×190-520 | > 560 | 3 x 400 | 85 | 3 x 400 | 37 | 28 | 3 |

| VS 4100 | 320 – 850 | 3×190-520 | > 560 | 3 x 400 | 100 | 3 x 400 | 45 | 87 | 3 |

| VS 4118 | 320 – 850 | 3×190-520 | > 560 | 3 x 400 | 118 | 3 x 400 | 55 | 87 | 3 |

| VS 4158 | 320 – 850 | 3×190-520 | > 560 | 3 x 400 | 158 | 3 x 400 | 75 | 87 | 3 |

| VS 4198 | 320 – 850 | 3×190-520 | > 560 | 3 x 400 | 198 | 3 x 400 | 93 | 87 | 4 |

| VS 4228 | 320 – 850 | 3×190-520 | > 560 | 3 x 400 | 228 | 3 x 400 | 110 | 87 | 4 |

| VS 4268 | 320 – 850 | 3×190-520 | > 560 | 3 x 400 | 268 | 3 x 400 | 132 | 87 | 4 |

*AC power available only for MP (MultiPower) models.

** Input voltage necessary to obtain 100% of rated motor power.

*** Typical motor power. It is recommended refer to the rated motor current when selecting the VASCO Solar – VAriable Speed COntroller model.

General specifications

| Rated ambient temperature | -10° to 50°C (14° – 122°F) |

| Operating temperature | -10° to 60°C (14° – 140°F) |

| Max altitude at rated current | 1000 m |

| Protection degree | IP66 (NEMA 4X) (Size 2) IP54 (NEMA 12) (Size 3, 4) |

| Digital outputs (configurable as N.O or N.C) | 1. Motor run signal 2. Alarm signal |

| Analog inputs (10 or 15 VDC): | 1. 4-20 mA 2. 4-20 mA 3. 4-20 mA or 0 – 10 VDC 4. 4-20 mA or 0 – 10 VDC |

| Digital inputs | 4 digital inputs, configurable as N.O. or N.C., for motor run/stop |

| Communication | MODBUS RTU RS485 Bluetooth® SMART (4.0) |