Centrifugal pump

Built-in inverter module (MINT)

The helical rotor pump

4HS “H” pumps are equipped with a helical rotor that moves within a double-helix rubber stator.

The rotor is made of AISI 304 stainless steel and coated with a hard chrome surface.

During operation, the rotor moves on the rubber surface and is lubricated by the pumped water.

The flow rate is directly proportional to the pump speed while the pressure supplied is kept almost constant.

In this way, unlike a centrifugal pump, the helical rotor pump provides high head even at low rpm, ensuring water on surface even with very low available power or low solar irradiation.

In addition, the helical rotor pumps feature higher hydraulic efficiency than centrifugal pumps having the same flow. This saves in the number of solar panels necessary for the application.

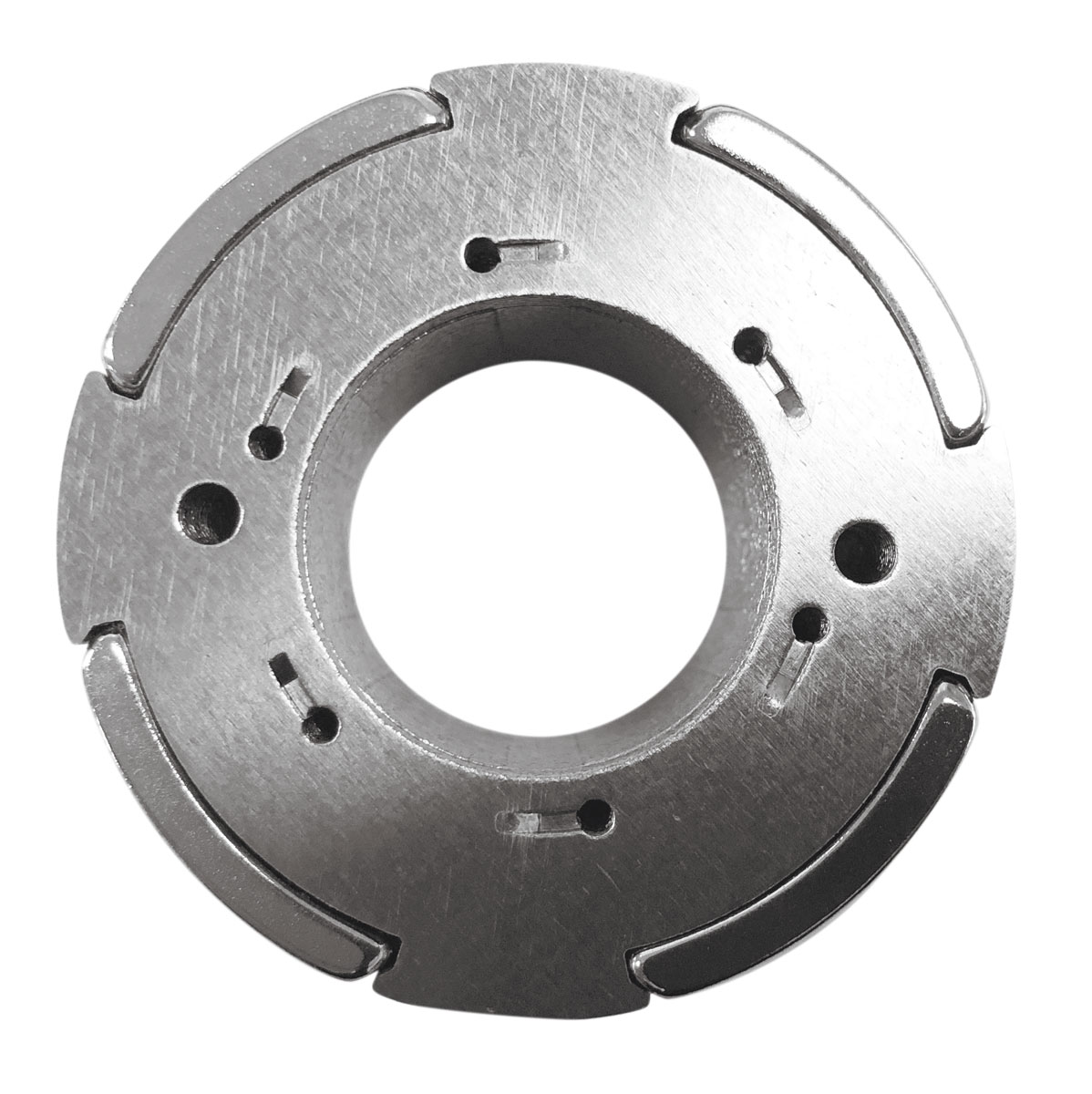

Motor

- Permanent magnet motor.

- Resined and incapsulated stator made of AISI 304 stainless steel.

- Water-cooled rotor.

- Kingsbury thrust bearing.

Permanent magnet motor

4HS MP pumps are equipped with a permanent magnet motor.

The rotor uses Neodymium magnets coated with thin layers of copper and nickel to ensure greater reliability and durability in addition to superior magnetic performance.

High motor efficiency and starting torque make it possible for the pump to run even in

low-light conditions.

The integrated inverter module converts DC energy into useful electrical energy to drive the motor efficiently and, at the same time, adjusts the pump speed according to the available irradiation, maximising the power extracted (MPPT).

Overload, overheating, dry-run protections are integrated on board.